Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Hydraulic Cylinder machining Process.

General cylinders are used chrome-plated rods for piston rods, pistons made of 45 steel, that is, the piston and piston rod are separate.

The long cylinder piston rod is made of 45 steel, its processing process route is: forging (rolling material) - undercutting - tempering - straightening - machining - surface quenching, tempering - straightening -Rod head welding - machining - grinding - stress relief annealing - polishing - hard chrome plating - polishing - cleaning - assembly assembly.

Piston rod heat treatment is the key process to ensure the intrinsic quality and mechanical properties of the piston rod, the quality of heat treatment is directly related to the life and reliability of the entire hydraulic system, if improper heat treatment, resulting in early fracture of the piston rod in the process of use, the light damage to other parts, in serious cases, may cause the destruction of the entire equipment and casualties.

Hydraulic cylinder is an important executive element in the hydraulic system of construction machinery, used to perform reciprocating motion and drive construction machinery to complete various functions. The piston rod is the key force transmission parts with high technical requirements to connect the piston and working parts in the hydraulic cylinder, which needs to bear large tensile stress during the working process.

Deeleap factory is mainly producing all kinds of high pressure hydraulic pumps and cylinders.

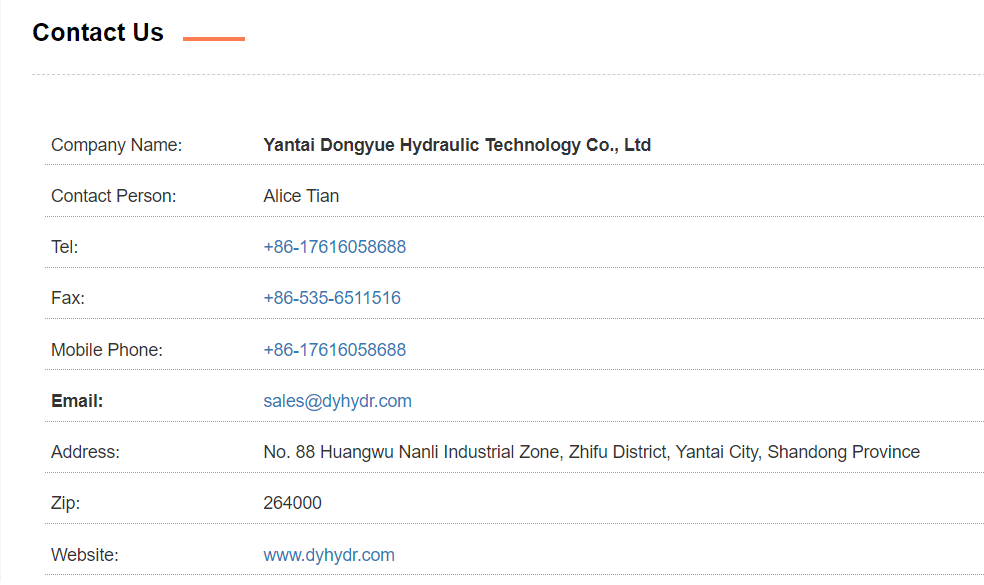

For more details, pls view www.dyhydr.com.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.